vessels

The following are the three main vessels I worked on in a lead role as a commercial naval architect.

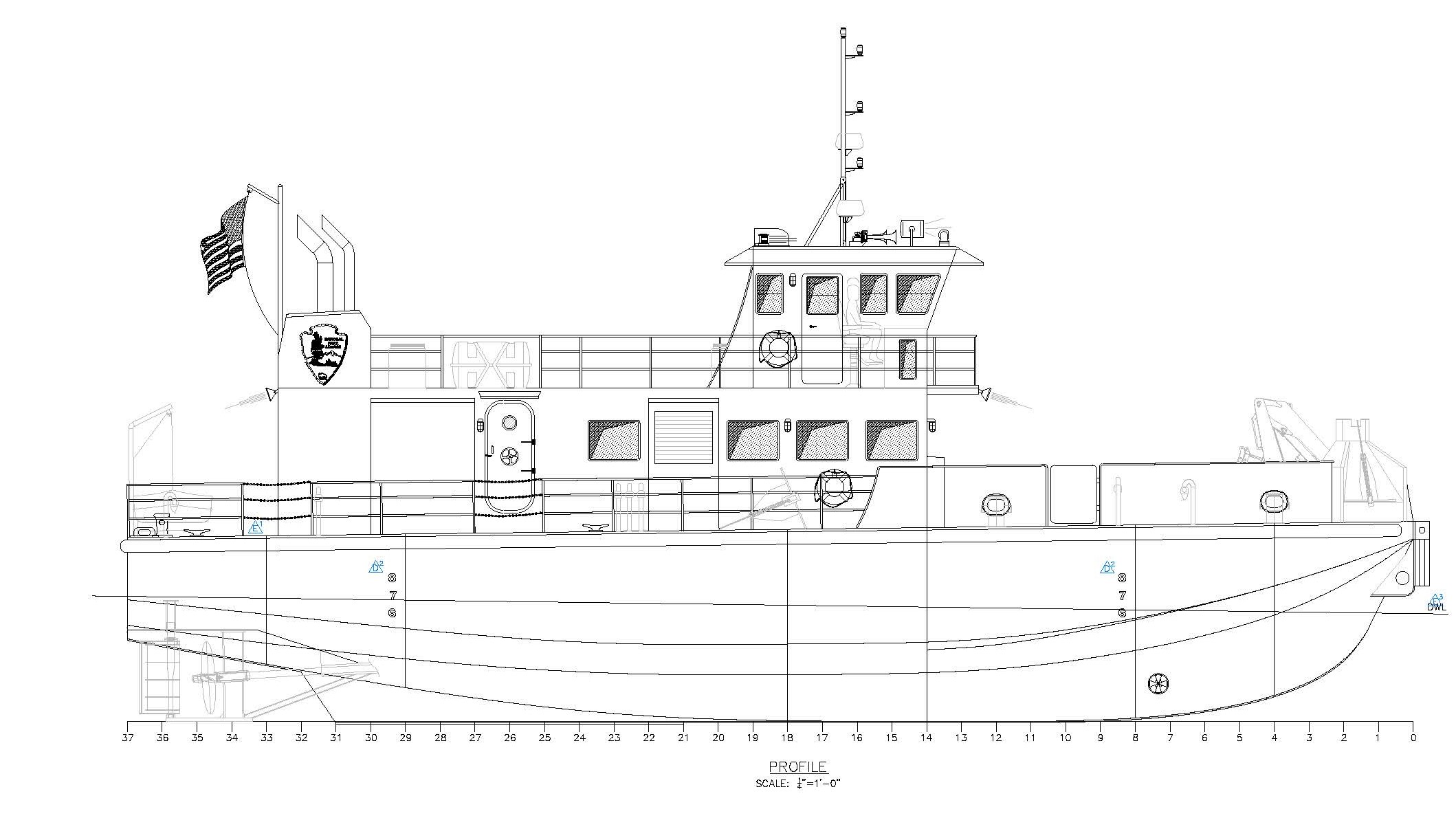

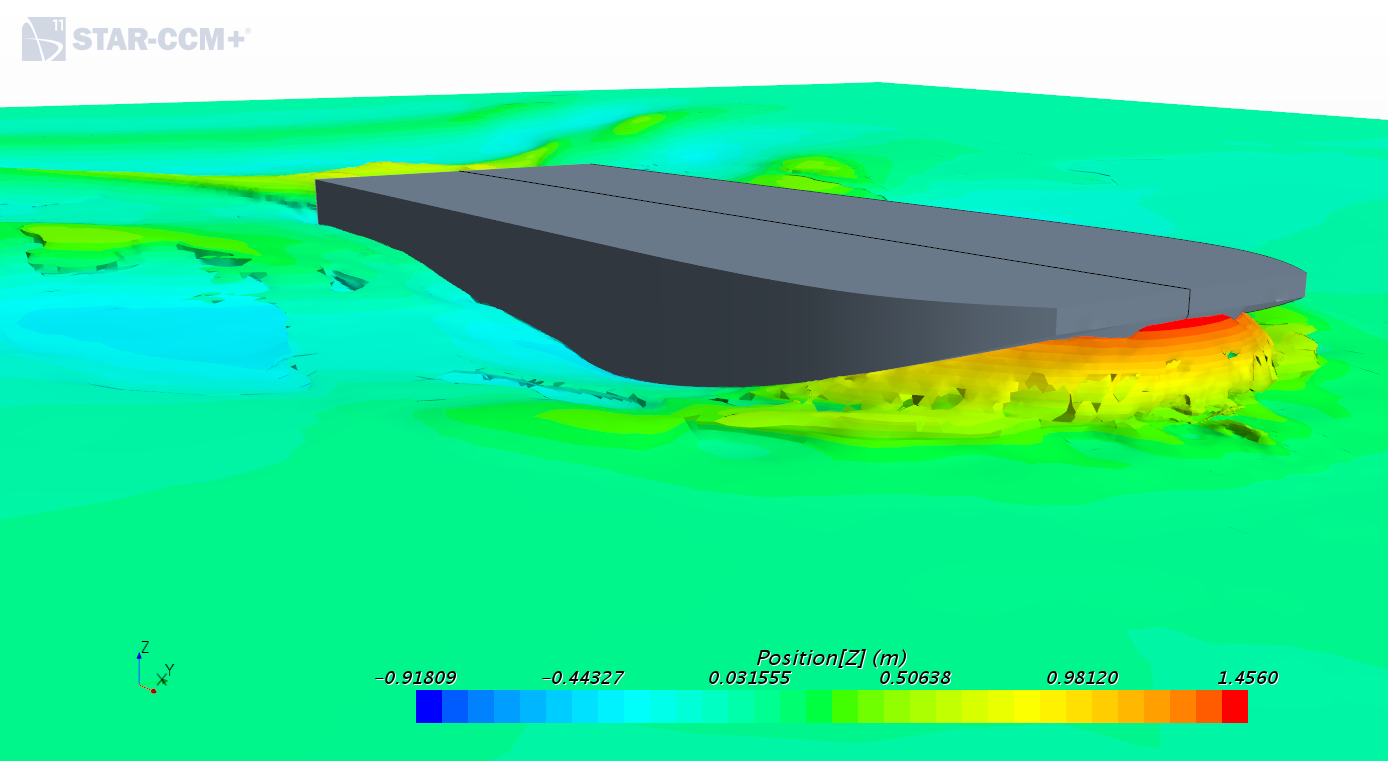

US National Park Service Annie Moore

The Annie Moore is a 74 ft steel-hulled Subchapter T passenger and utility vessel for the National Park Service, servicing the Statue of Liberty Monument and Ellis Island in New York Harbor. The design included an ice-classed hull and propulsion system. CFD was used in design to help optimize vessel hull shape and ensure suitable hydrodynamics. The basis of design was the US Army Corps of Engineers 60 ft debris collection vessel Reynolds. I completed the design drawing package, structural analysis, weights and centers, Subchapter T stability, tonnage calculations, and CFD for this vessel.

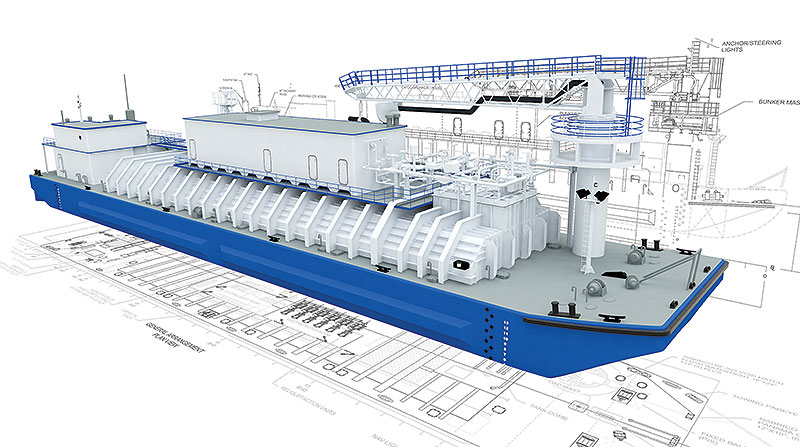

Liquified Natural Gas (LNG) Bunkering Barge Clean Jacksonville

The Clean Jacksonville was the first LNG bunkering barge built in North America. Along with colleagues at Bristol Harbor Group, I was responsibile for the design and engineering of the barge, including technical and shipyard support during construction. Additionally, I was highly involved in the regulatory process with the USCG, ABS and other entities to obtain design approval for a vessel outside of existing USCG and ABS regulatory policy. The barge was designed to bunker the first class of LNG-fueled containerships operated by Tote Maritime, running Jones Act routes between Jacksonville, FL and Puerto Rico. The barge is a single 2000m3 tank, equipped with French-based GTT’s membrane style containment technology. Gasentec, a Korean-based company, was responbile for the cryogenic handling system design and analysis. The barge was built at Conrad Orange Shipyard, in Orange, TX. It includes onboard re-liquefaction to re-convert gaseous NG to LNG, maintaining a low internal tank pressure. A transfer boom allows cryogenic LNG transfer from barge to ship. I was heavily involved in all aspects of the regulatory, design and build process. Major efforts included structural design and analysis of the barge, stability, weights and centers, on-board auxiliary system design, and overall system integration.

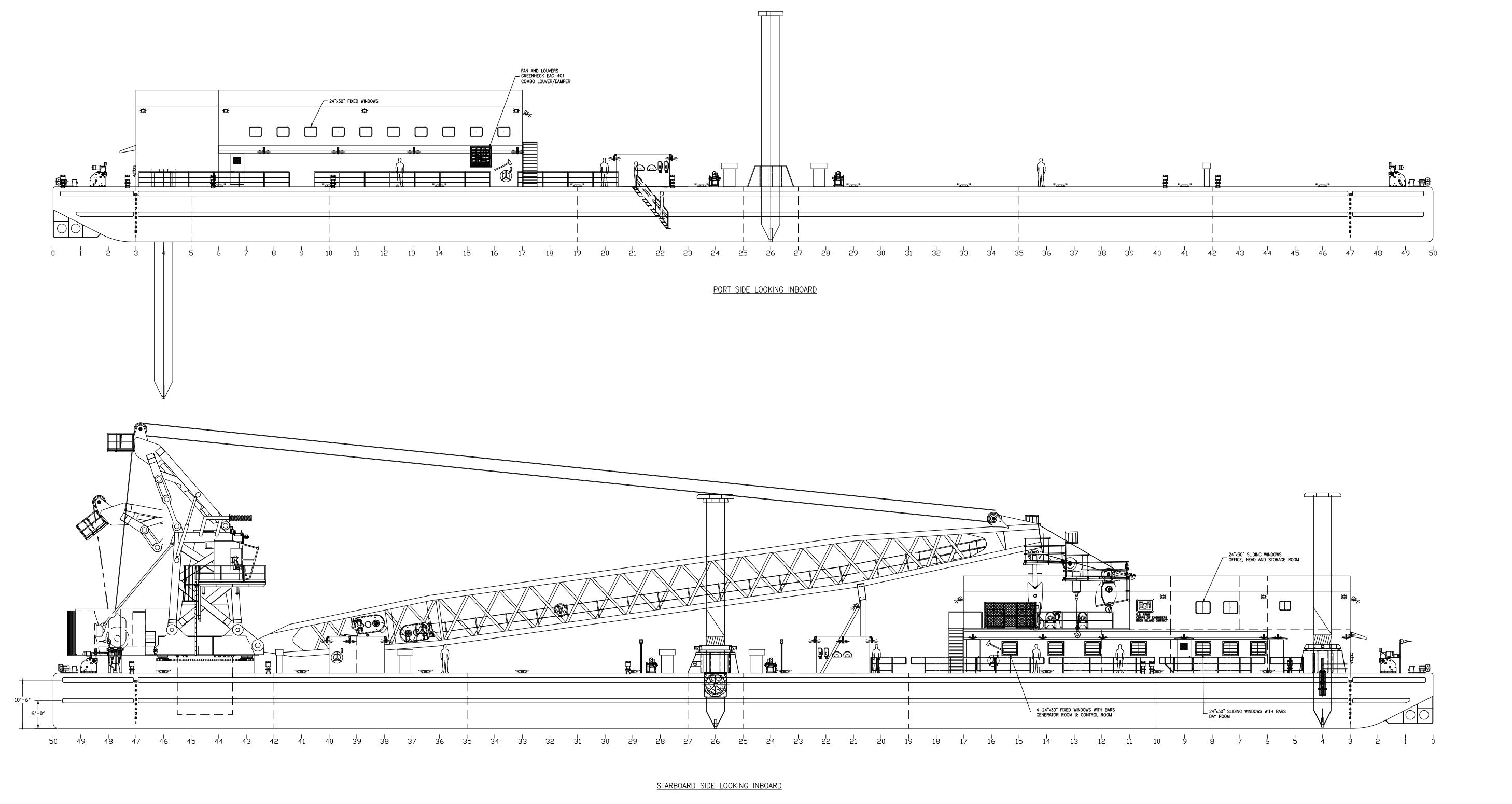

US Army Corps of Engineers Floating Crane Barge Quad Cities

Quad Cities is a 300ft long, 68ft wide floating crane barge with a 500 ton max lift capability. It was designed for US Army Corps of Engineers Rock Island District, as a replacement crane barge to service the sector gates on the inland waterways. I was lead design on this project, conducting all structural and stability calculations, in addition to a full ABS approved design drawing package. The barge has significant longitudinal structure to be able to handle the bending moment generated when conducting a 1,000,000 lb lift, while internally counter-ballasted on the opposite end with seawater. The barge was fabricated by Conrad Shipyards in Morgan City, La. The crane was designed and fabricated by Seatrax of Houston, Tx.